Bus Bar Insulator Manufacturers in Chakan – Shree Laxmi Enterprises

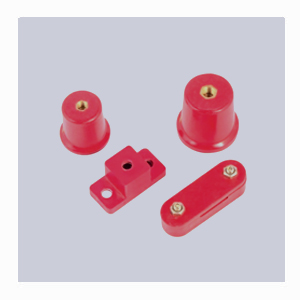

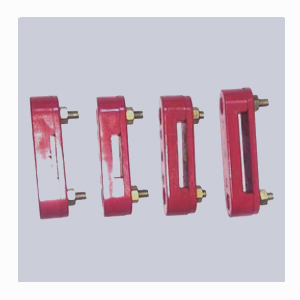

Shree Laxmi Enterprises is the leading bus bar insulator manufacturers in Chakan. Our top-rate insulator enhances power system operation our business provides an extensive collection of high-quality durable and top-performing bus bar insulator for power system applications.

We are bus bar insulator suppliers, dealers, distributors, traders and wholesalers in Chakan. Our product range includes multiple size and shape options to fit different applications which can effortlessly blend with your current infrastructure.

Pre buy our insulator to enable better efficiency and safer electrical systems operation together Our Company operate in extreme conditions because we possess high-dielectric-strength materials that survive both mechanical stress and environmental exposure.

How we are manufacturers of Bus Bar Insulator:

The bus bar insulator manufacturing process is a dedicated industry where the factors are mechanical resilience and electrical insulation. Both bulk molding compound and sheet molding compound are used as possess excellent insulation, resistance to heat, as well as flames.

For applications involving high voltage, porcelain is selected for strength and weathering resistance. Used for encapsulation, giving excellent mechanical and environmental protection.

Compression molding this is a popular technique in which the insulating material is filled into a preheated mold, and hydraulic pressure is then applied to produce the insulator. It is used for thermoplastics, where the material is injected into a mold.

Types of Bus bar Insulator:

Being as bus bar insulator suppliers and dealers in Chakan, there is different functional categories and the selection of insulating materials. Some of the types as follow.

-

Porcelain

Ceramic emerges when fire-clay heating leads to solid non-conductive material. This material structure demonstrates both water resistance and pollutant protection together with electrical tracking prevention thus making it appropriate.

-

Epoxy Resin

Conversion of thermosetting polymer epoxy resin leads to solid insulating material status after complete curing process completion. The insulation system of medium-voltage switchgear distribution boards depends on epoxy resin.

-

Composite Polymers

Man-made insulator emerges from combining fiberglass fibres with polymer resins to generate durable lightweight components. The popularity of these materials sky-rocketed because our hydrophilic nature stops flashovers from happening in polluted regions.

-

Glass

Artistic glass formulations with toughened composition find use in certain high-voltage insulator applications. The material's layer provides superior resistance against surface soiling and collects minimal water as it naturally repels liquid substances.

-

Heat Shrink Materials

Heat Expandable Tubes of Polyolefin Material Form Flexible Insulating Tubes Which Constrict around Bus bars During Heating Cycles. Using heat shrinkage technology allows successful insulation of shape-complex bus bar.

Technical Specification of Bus bar Insulator:

We have added below a technical sheet of bus bar insulator in Chakan that provides more technical information such as:

| Feature | Specification | Notes |

|---|---|---|

| Material | Bulk Molding Compound, Sheet Molding Compound, Epoxy Resin, Porcelain, Polyamide resin with glass fibre. | Choice of material affects mechanical and electrical strength, temperature resistance, and arc resistance. |

| Rated Voltage | Ranges from low voltage e.g., 660V to high voltage e.g., several kV | Varies significantly based on application. |

| Voltage Withstand Dielectric Strength | Ranges from several kV e.g., 6kV, 8kV, 10kV, 15kV, 25kV | Indicates the insulator's ability to withstand high voltages without breakdown. |

| Operating Temperature | Typically -40°C to +140°C | Ensures functionality in diverse environmental conditions. |

| Tensile Strength | Varies e.g., 500 lbs, 600 lbs, 1000 lbs, 1500 lbs | Indicates the insulator's ability to withstand pulling forces. |

| Torque Strength | Varies e.g., 6 ft-lbs, 10 ft-lbs, 20 ft-lbs, 40 ft-lbs | Indicates the insulator's resistance to twisting forces. |

| Arc Resistance | >180 seconds ASTM D-495 | Measures the insulator's ability to withstand electrical arcs. |

| Water Absorption | 0.2% ASTM D-570 | Indicates the insulator's resistance to moisture. |

| Tracking Resistance | 3 W/min ASTM D-2302 | Measures the insulator's resistance to surface current leakage. |

| Insert Material | Brass, Steel with Zinc coating | Provides a threaded point for secure connection. |

| Screw Thread Size | M5, M6, M8, M10, etc. | Varies depending on insulator size and application. |

| Flame retardancy | UL94 V-0 ratings are common. | |

| Dimensions | Varied dimensions depending on the specific application. | Height, width, and diameter vary greatly. |

Features and Benefits of Bus bar Insulator:

Serve as bus bar insulator distributors and traders in Chakan, our electrical systems largely rely on this. For this some of the benefits as follow.

-

Improved Electrical Safety

Bus bar insulator basically prevents electrical contact while we significantly reduce the likelihood of receiving electric shocks and generating short circuits. High-voltage systems particularly need this measure above all else.

-

Reduction of Fire Hazards

Most bus bar insulator has flame-retardant materials that act as fire protection systems to mitigate threat level. Such materials exhibit dual functionality upon occurrence of electrical faults since we hold and extinguish flames.

-

Provision of Mechanical Protection and Support

We provide essential mechanical stability since we improve protective means against physical damage and shouldering ability in addition to deflection resistance against external forces.

-

Improved System Reliability

We prevent electrical faults while ensuring mechanical system stability which leads to increased electrical system reliability and reduces maintenance costs.

-

Protection from Corrosion

Insulator as coatings forms a protective barrier for shielding bus bars from environmental damage which allows the bus bars to withstand longer durations.

Applications of Bus bar Insulator:

As s bus bar insulator wholesalers in Chakan, we play a vital role in electrical systems by providing critical support and insulation to bus bar. Some of the applications as follow.

-

Switchgear and Switchboards

We are often used on switchgear and switchboards to support as well as electrically separate bus bar. This helps distribute electrical power safely and efficiently.

-

Power Distribution Units

In power distribution enclosures, we play a critical role in sustaining the integrity of the electrical contacts and avoiding short circuits.

-

Substations

Substations, the backbone of power transmission and distribution, depend upon bus bar insulator to house and insulate high-voltage bus bars.

-

Industrial Control Panels

Industrial control panels use bus bar insulator to structure and insulate bus bars, providing effective power distribution in industrial machines and systems.

-

Bus ways and Bus Ducts

Such systems employ bus bar insulator for insulating and supporting the bus bars inside enclosed ducting and offer a reliable and safe power distribution method within commercial and industrial structures.

Shree Laxmi Enterprises is the best bus bar insulator manufacturers in Chakan, provides a full complement of high-performance bus bar insulators suitable for use in an extensive range of power system applications.

Supported by phenomenally great technical specifications such as dielectric insulation and thermal reliability, our products find ideal applications in industry switchgears, substations, and control panels, nullifying electrical risks on a day-to-day basis and ensuring maximum life cycle for a system.